Jewelry Making

Jewelry Making

Learning the intricate art of jewelry creation through 3D printing and metalworking

Process of Jewelry Creation

Through the use of 3D printing technology, I started learning about the process of jewelry making. I audited a course offered by ODU’s art department Arts291/391/392/393 Metalsmithing and Jewelry.

Self directed research uncovered jewelry making with precious metals is an intricate process. It is a form of art.

This has not deterred my efforts. I recognized FDM printing does not produce appropriate models for use in later stages of jewelry making. This led to a purchase of a new tool.

The Process

Step 1: Designing - Modeling in 3D software. Fusion360 or Rhino7. Jewelry industry uses Rhino7 and it’s cheaper.

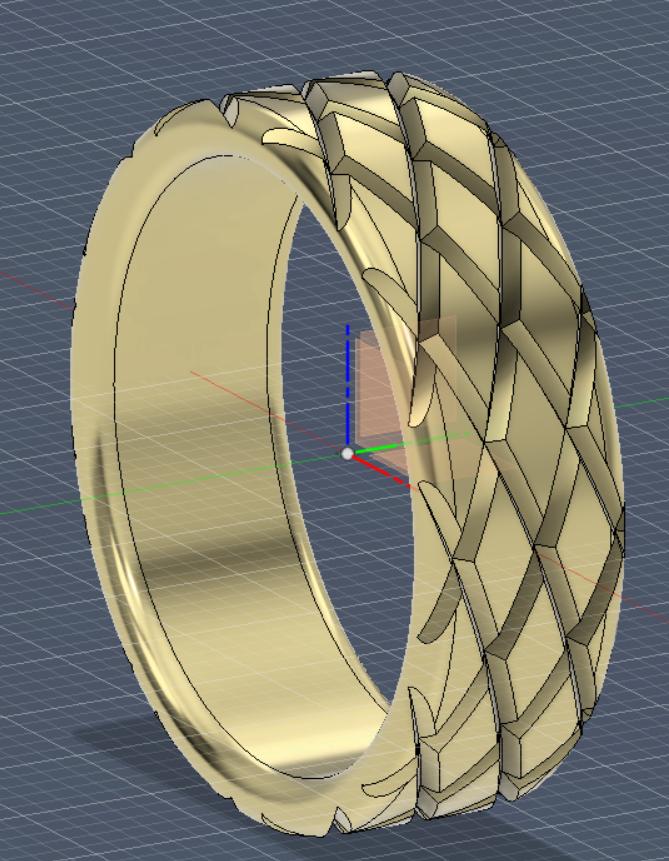

A ring design of mine created in Fusion360

A ring design of mine created in Fusion360

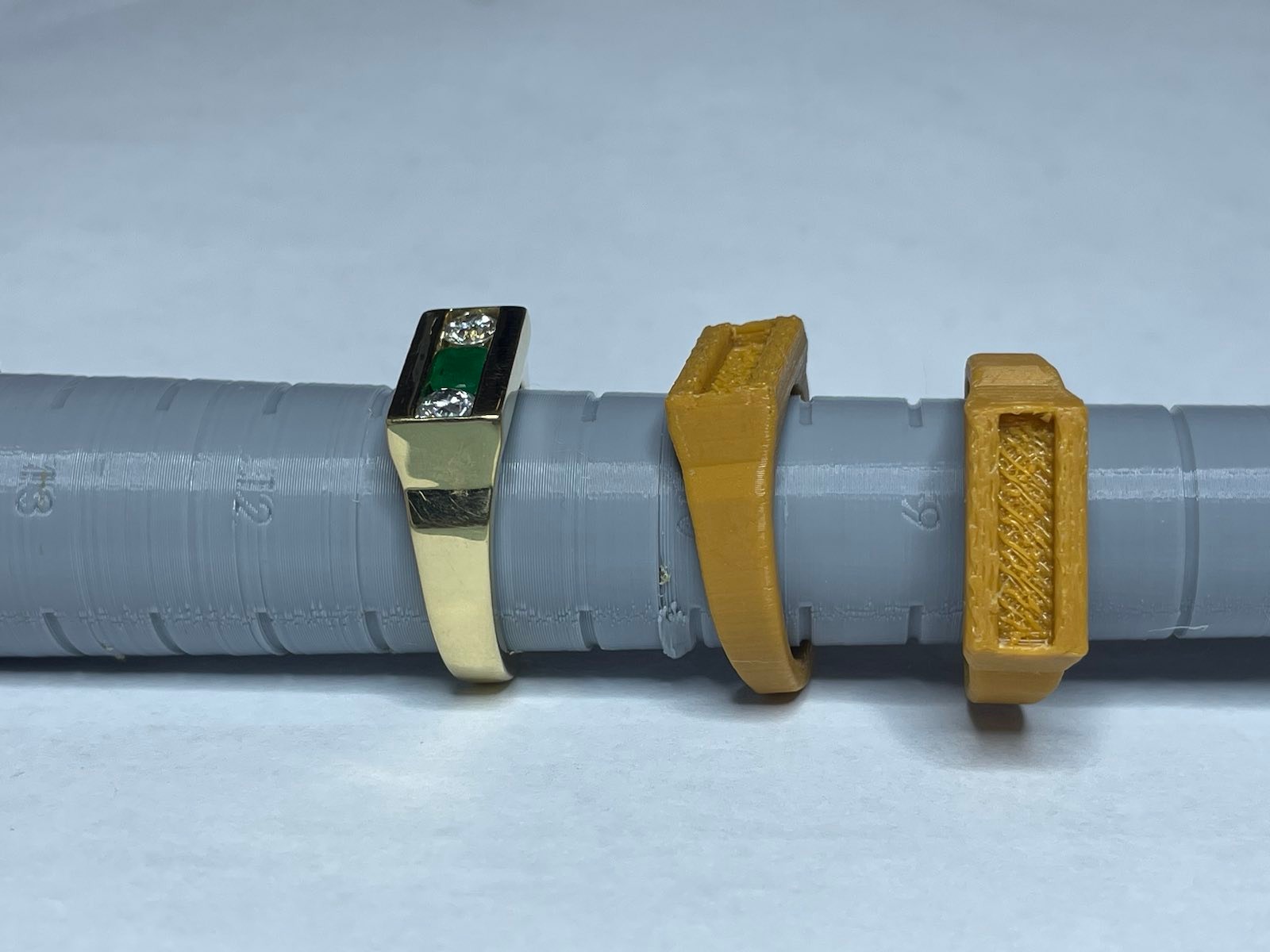

Step 2: Printing Prototypes - FDM is used as a proof of concept to inspect dimensions.

Step 3: Casting - Casting is an intricate process that requires significant amounts of energy. States of matter change from solid to molten metal and cooled back to solid. Lost wax casting.

Step 4: Stone Setting - If stones are desired for the piece, sizing of stones and type are considered and then set appropriately according design requirements.

Step 5: Polishing

Step 6: Find market entry.

Resin Printing

Yet to be used, I added a Creality Halot One resin printer. Resin printers are capable of producing significantly more detailed prints and printing mediums which removes the presence of layering.

Resin printing is an extremely intricate process and requires several other tools, personal protective equipment (PPE), ventilation, workspace expansion, and UV curing and washing capabilities is additional processing unique to resin printing.

Casting Process

There are various techniques used to create jewelry. Casting, Sandcasting, and a hand made process to name a few.

3kg melting furnace with varying material weights which can be smelted

3kg melting furnace with varying material weights which can be smelted

This is a 3kg melting furnace. Pictured are varying material weights which can be smelted. Their capacities vary due to their different densities.

Density of Materials

- Au Gold - 19.3 g/cm³

- Cu Copper - 8.96 g/cm³

- Ag Silver - 10.49 g/cm³

- Al Aluminum - 2.7 g/cm³

- Pb Lead - 11.34 g/cm³

Reference: Periodic Table

Polishing and Stone Setting

Polishing Techniques

The final finishing process involves multiple stages of progressively finer abrasives:

- Coarse Polishing: 220-400 grit sandpaper for initial surface preparation

- Fine Polishing: 800-1200 grit for smooth surface achievement

- Compound Polishing: Rouge and tripoli compounds for mirror finish

- Final Buffing: Soft cloth wheels for ultimate shine

Stone Setting Methods

- Prong Setting: Secure and showcases stone brilliance

- Bezel Setting: Protective metal rim around stone perimeter

- Pave Setting: Multiple small stones set closely together

- Channel Setting: Stones held between two metal rails

Tools and Equipment

- Flex Shaft: Variable speed rotary tool for precision work

- Setting Burs: Specialized drill bits for stone seats

- Prong Pushers: Tools for securing metal prongs

- Stone Tweezers: Precision handling of gemstones

Market Entry

Ring mandrel for sizing and shaping rings to standard sizes

Ring mandrel for sizing and shaping rings to standard sizes

Business Strategy

Developing a sustainable jewelry business requires multiple revenue streams:

Custom Design Services

- Client Consultation: Understanding design preferences and budget

- 3D Visualization: Using Fusion360 for customer approval

- Prototyping: FDM printing for fit and form validation

- Final Production: Investment casting for precious metals

Educational Workshops

- Basic Metalsmithing: Teaching fundamental techniques

- 3D Design for Jewelry: CAD software training

- Casting Workshops: Hands-on experience with lost-wax process

- Stone Setting Classes: Precision work with gemstones

Online Presence

- Portfolio Website: Showcasing completed pieces

- Social Media Marketing: Instagram and Pinterest for visual appeal

- E-commerce Platform: Direct sales through Etsy and custom website

- Video Content: YouTube tutorials for technique demonstration

Quality Standards

- Hallmarking: Proper metal purity stamps

- Documentation: Certificates for precious stones

- Photography: Professional images for marketing

- Packaging: Branded boxes and care instructions

Pricing Strategy

- Material Costs: Gold, silver, and gemstone pricing

- Labor Hours: Detailed time tracking for accurate pricing

- Market Research: Competitive analysis for positioning

- Profit Margins: Sustainable 40-60% markup for custom work